|

|

Pico-Ion PPB Oxygen Sensors

UHP Version | MS

Version |

PDF

|

| The

Pico-Ion PPB oxygen sensor and

electrochemical oxygen purity sensor

represent the only real innovations

electrochemical sensor technology in

decades.

Quality,

a critical element of customer satisfaction,

is taken very seriously at Analytical

Industries Inc. All products are

manufactured under an independently

certified Quality System that complies with

ISO 9001:2008,

MDD/93/42 EEC (European CE),

ISO 13485:2003 (Health Canada) and

FDA regulatory standards. To further

ensure the confidence of our global customer

base, analyzers designed for use in

hazardous areas are independently

ATEX and/or UL (pending) certified. Quality,

a critical element of customer satisfaction,

is taken very seriously at Analytical

Industries Inc. All products are

manufactured under an independently

certified Quality System that complies with

ISO 9001:2008,

MDD/93/42 EEC (European CE),

ISO 13485:2003 (Health Canada) and

FDA regulatory standards. To further

ensure the confidence of our global customer

base, analyzers designed for use in

hazardous areas are independently

ATEX and/or UL (pending) certified. |

Pico-Ion UHP PPB Oxygen Sensor

The unique features of this breakthrough

in sensor technology are a proprietary

sensing electrode material and a gas chamber

design that maximizes the rate of reaction

above the sensing electrode while minimizing

both the amount of oxygen that dissolves

into the electrolyte and the temperature

dependence of the sensor’s output, thereby

ensuring long-term stability. This compact

self contained package requires no

maintenance or periodic addition of

chemicals and is easily replaced at the end

of its 15 month service life. The

capabilities of the resulting sensor are:

| Accuracy: |

+1% FS under

constant conditions |

| Sensitivity: |

<0.5 PPB |

| Noise level: |

<0.2 PPB |

| Stability: |

<1 ppb over temperature

fluctuations of +10ºF |

| Low range: |

0-100 PPB full scale |

| Response time: |

90% of full scale in <60 seconds

|

| Recovery to: |

10 PPB from 1 minute exposure to

9 PPM in 15 minutes

1 PPB from 1 minute exposure to 9

PPM in 60 minutes

1 PPB from 5 minute exposure to 1

PPM in 30 minutes |

| Expected life: |

15 months in normal applications |

Pico-Ion MS PPB Oxygen Sensor

Drawing upon the features of the UHP

sensor, the MS sensor provides the signal

output and stability required for oxygen

analysis above 5 PPB to fill a much needed

cost effective solution between expensive

sub-PPB sensors and the limitations of

historical galvanic trace PPM sensors.

| Accuracy: |

+1% FS under

constant conditions |

| Sensitivity: |

<5 PPB |

| Noise level: |

<2 PPB |

| Stability: |

<10 ppb over temperature

fluctuations of +10ºF |

| Low range: |

0-1 PPM full scale |

| Response time: |

90% of full scale in <20 seconds

|

| Recovery to: |

1 PPM from 30 second exposure to

air in 45 minutes

10 PPB from 5 minute exposure to 1

PPM in 15 minutes

10 PPB from 2 minute exposure to 9

PPM in 10 minutes |

| Expected life: |

24-36 months in normal

applications |

|

Galvanic Trace PPM Oxygen Sensors

0-10 PPM Version |

0-100 PPM Version |

PDF

|

| The

Pico-Ion PPB oxygen sensor and

electrochemical oxygen purity sensor

represent the only real innovations

electrochemical sensor technology in

decades. Applying this advanced technology

to traditional sensors produced a new

generation of trace PPM and percent sensors

that can be readily applied to a wide range

of applications in the industrial process

control, natural gas, medical, diving and

personnel safety markets.

Quality,

a critical element of customer satisfaction,

is taken very seriously at Analytical

Industries Inc. All products are

manufactured under an independently

certified Quality System that complies with

ISO 9001:2008,

MDD/93/42 EEC (European CE),

ISO 13485:2003 (Health Canada) and

FDA regulatory standards. To further

ensure the confidence of our global customer

base, analyzers designed for use in

hazardous areas are independently

ATEX and/or UL (pending) certified. Quality,

a critical element of customer satisfaction,

is taken very seriously at Analytical

Industries Inc. All products are

manufactured under an independently

certified Quality System that complies with

ISO 9001:2008,

MDD/93/42 EEC (European CE),

ISO 13485:2003 (Health Canada) and

FDA regulatory standards. To further

ensure the confidence of our global customer

base, analyzers designed for use in

hazardous areas are independently

ATEX and/or UL (pending) certified. |

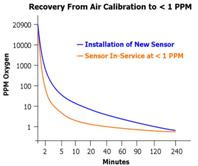

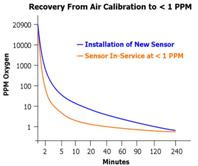

Galvanic 0-10 Trace PPM Oxygen Sensor

Exhibit superior stability at low PPM

oxygen levels, faster recovery from

excursions to high oxygen concentrations and

a longer service life than traditional

sensors.

A proprietary electrolyte that

demonstrates excellent compatibility with up

to 100% concentrations of carbon dioxide

(CO2) has made the XLT sensors the standard

for measuring oxygen contamination in

beverage grade CO2 and natural gas. Required

for continuous exposure to CO2 levels 0.5%,

the XLT sensors also feature an extended

operating temperature range of -20°C.

| Accuracy: |

+1% FS under

constant conditions |

| Sensitivity: |

<50 PPB |

| Low range: |

0-10 PPM full scale |

| Response time: |

90% of full scale in <7 seconds |

| Expected life: |

24-36 months in normal

applications |

| Recovery to: |

see illustration |

Galvanic 0-100 PPM Oxygen Sensor

The 0-100 PPM sensor carries over many of

the features of the more sensitive sensor

and was developed to provide a cost

effective analyzer solution for higher level

PPM oxygen analysis.

| Accuracy: |

+1% FS under

constant conditions |

| Sensitivity: |

<500 PPB |

| Low range: |

0-100 PPM full scale |

| Response time: |

90% of full scale in <13 seconds

|

| Recovery to: |

50 PPM from air

calibration in 45 minutes

|

| Expected life: |

24-36 months in normal

applications |

|

Galvanic Percent Oxygen Sensors

0-1% Range |

Generic |

PDF

|

|

Applying this advanced technology derived

from the Pico-Ion and electrochemical oxygen

purity innovations to traditional sensors

produced a new generation of percent sensors

that can be readily applied to a wide range

of applications in the industrial process

control, natural gas, medical, diving and

personnel safety markets.

Quality,

a critical element of customer satisfaction,

is taken very seriously at Analytical

Industries Inc. All products are

manufactured under an independently

certified Quality System that complies with

ISO 9001:2008,

MDD/93/42 EEC (European CE),

ISO 13485:2003 (Health Canada) and

FDA regulatory standards. To further

ensure the confidence of our global customer

base, analyzers designed for use in

hazardous areas are independently

ATEX and/or UL (pending) certified. Quality,

a critical element of customer satisfaction,

is taken very seriously at Analytical

Industries Inc. All products are

manufactured under an independently

certified Quality System that complies with

ISO 9001:2008,

MDD/93/42 EEC (European CE),

ISO 13485:2003 (Health Canada) and

FDA regulatory standards. To further

ensure the confidence of our global customer

base, analyzers designed for use in

hazardous areas are independently

ATEX and/or UL (pending) certified. |

Galvanic Oxygen Sensors for 0-1% Range

Most applications for percentage range

oxygen analysis emphasize the need for

longer life in order to minimize service

requirements. However, the transitioning

from high PPM to low percent oxygen analysis

area presents a grey area that adds

additional considerations.

The design of sensors for low level

measurements involves a delicate balance

between a higher

signal output

that improves stability by reducing the

influence of temperature and expected life.

The ability to recognize this issue and

offer a number of solutions, see chart

below, differentiates Analytical Industries

Inc. from our competitors and enables users

to select the best option for their

particular application.

| Sensor |

Output |

Response |

Stability |

Life |

| GPR-11-32 |

50 uA |

13 sec |

0.05% |

36 mos |

| XLT-11-24 |

50 uA |

13 sec |

0.05% |

24 mos |

| XLT-11-15 |

180 uA |

30 sec |

0.03% |

15 mos |

| XLT-11-1523 |

300 uA |

13 sec |

0.02% |

10 mos |

| XLT-11-1513 |

500 uA |

10 sec |

0.01% |

5 mos |

Galvanic Percent Oxygen Sensor

Exhibit superior performance,

reliability, extended life and extended

operating temperature range which are

critical to meeting the need for oxygen

measurements imposed by today’s industrial

process, medical, diving, natural gas,

safety and welding applications.

XLT sensors have an extended operating

temperature range of –20°, demonstrate

excellent compatibility with carbon dioxide

concentrations up to 100% and are required

for continuous exposure to carbon dioxide

levels above 0.5%.

| Accuracy: |

+1% FS under

constant conditions |

| Sensitivity: |

<0.5% of full scale range |

| Low range: |

0-1% full scale |

| Response time: |

90% of full scale in <13 seconds

|

|

Recovery to: |

0.1% from exposure

to air <30 seconds |

| Expected life: |

24-120 months in normal

applications |

|

Galvanic Oxygen Purity Sensor

Background |

PDF

|

Quality,

a critical element of customer satisfaction,

is taken very seriously at Analytical

Industries Inc. All products are

manufactured under an independently

certified Quality System that complies with

ISO 9001:2008,

MDD/93/42 EEC (European CE),

ISO 13485:2003 (Health Canada) and

FDA regulatory standards. To further

ensure the confidence of our global customer

base, analyzers designed for use in

hazardous areas are independently

ATEX and/or UL (pending) certified. Quality,

a critical element of customer satisfaction,

is taken very seriously at Analytical

Industries Inc. All products are

manufactured under an independently

certified Quality System that complies with

ISO 9001:2008,

MDD/93/42 EEC (European CE),

ISO 13485:2003 (Health Canada) and

FDA regulatory standards. To further

ensure the confidence of our global customer

base, analyzers designed for use in

hazardous areas are independently

ATEX and/or UL (pending) certified.

|

An innovative and cost effective solution

that provides 2 years of continuous

measurements of up to 100% oxygen

concentrations in a maximum suppressed range

of 90-100% full scale with minimum drift,

extended periods between calibration,

unaffected by vibration and minor amounts of

particulates and moisture.

| Accuracy: |

+1% FS under

constant conditions

Inherent 0.1% after calibration with

100% oxygen |

| Sensitivity: |

0.5% of full scale rane |

| High range: |

90-100% suppressed full scale

range |

| Response time: |

90% of full scale in <13 seconds

|

| Expected life: |

24 months at 100% oxygen levels |

|

Background

Historically, the production of pure oxygen

has been confined to medical grade oxygen

(99.0%). However, the demand for oxygen is

expanding rapidly due to developments in

chemical processes requiring elevated levels

of oxygen (85-95%) that boost yields and

reduce emissions without significant cost

increases. To a lesser extent the growth of

transfilling oxygen (92%) cylinders for home

care use. The oxygen supplied can be

produced cryogenically, by pressure (PSA) or

by vacuum (VSA) swing adsorption methods.

Analyzers based on paramagnetic sensors

have been the primary method of measuring

oxygen purity. These sensors offer highly

accurate results especially at the

suppressed ranges of 98-100% oxygen.

However, they are very sensitive to changes

in the flow rate of the sample gas, the

presence of minute particulates and

moisture, temperature variations and

vibration. As a result, compensating for

these characteristics is expensive and

requires frequent calibration of

paramagnetic oxygen analyzers.

Analyzers based on galvanic oxygen

sensors have always generated interest for

oxygen purity measurements because they are

specific to oxygen, versatile, low

maintenance and less expensive. However,

short sensor life and drift in the sensor’s

signal output with time have precluded their

use.

Major

Advancement in Galvanic Sensor Technology

An advanced galvanic sensor has been

developed that is capable of accurately

measuring 100% oxygen concentrations

continuously over a two (2) year period.

This proprietary design addresses the

challenges of: 1) providing a sufficient

amount of anode material to support the

reduction of oxygen over several years,

2) maintaining at all times a sufficient

concentration of hydroxyl ions to support

the reduction of oxygen at and near the

sensing electrode, and, 3) preventing the

build-up of PbO at and near the sensing

electrode that can cause the signal output

of the sensor to drop or drift with time.

Through proprietary means the production

rate of the reaction product is controlled

without sacrificing either the fast response

time (less than 13 seconds) or any of the

features (described above) of analyzers

based on galvanic sensors. The performance

of this proprietary sensor was confirmed

over 14 months of testing and exhibited

excellent stability in 100% oxygen.

Performance

Test Results

With the sensor and sample gas lines

temperature controlled and the signal output

of the sensor compensated fro ambient

pressure variations, it was possible to

measure oxygen in the suppressed range of

90-100% with less than +1% of full scale

(+0.1% oxygen) accuracy. The calibration was

checked periodically and found to be within

+1% of full scale over the 14 month test

period suggesting the interval between

calibrations could be extended to several

months.

To demonstrate the stability of the new

analyzer, 99.5% oxygen was introduced

(typically the threshold for manufacturers

of pure oxygen) for 30 days and the output

trended. The maximum variation in the signal

output is +0.1% oxygen over a 24 hour period

and is primarily attributed to the variation

in ambient temperature.

Based on the foregoing, the new analyzer

galvanic sensor based analyzer offers a very

viable and cost effective solution for

measuring elevated oxygen levels up to and

above 99.5% in a maximum suppressed range of

90-100% with excellent accuracy and

stability, a significant reduction in

calibration requirements, unaffected by

vibration and minor amounts of particulates

and moisture. |

美国AII氧分析仪传感器XLT-12-123 美国AII氧分析仪传感器PSR-12-22 美国AII氧分析仪传感器PSR-12-24

美国AII氧分析仪传感器PSR-12-223 美国AII氧分析仪传感器XLT-11-15 美国AII氧分析仪传感器PSR-11-21

美国AII氧分析仪传感器PSR-11-213 美国AII氧分析仪传感器PSR-11-23 美国AII氧分析仪传感器PSR-11-233

美国AII氧分析仪传感器PSR-11-25 美国AII氧分析仪传感器PSR-11-77 美国AII氧分析仪传感器PSR-11-54 美国AII氧分析仪传感器PSR-11-52

美国AII氧分析仪传感器PSR-11-39

| 产品图片 |

产品名称/型号 |

产品简单介绍 |

|

|

美国AII氧分析仪传感器XLT-12-123

美国AII XLT-12-123

|

|

|

|

美国AII氧分析仪传感器PSR-12-22

美国AII PSR-12-22

|

|

|

|

美国AII氧分析仪传感器PSR-12-223

美国AII PSR-12-223

|

|

|

|

美国AII氧分析仪传感器PSR-12-24

美国AII PSR-12-24

|

|

|

|

美国AII氧分析仪传感器XLT-11-15

美国AII XLT-11-15

|

|

|

|

美国AII氧分析仪传感器PSR-11-21

美国AII PSR-11-21

|

|

|

|

美国AII氧分析仪传感器PSR-11-213

美国AII PSR-11-213

|

|

|

|

美国AII氧分析仪传感器PSR-11-23

美国AII PSR-11-23

|

|

|

|

美国AII氧分析仪传感器PSR-11-233

美国AII PSR-11-233

|

|

|

|

美国AII氧分析仪传感器PSR-11-25

美国AII PSR-11-25

|

|

|

|

美国AII氧分析仪传感器PSR-11-77

美国AII PSR-11-77

|

|

|

|

美国AII氧分析仪传感器PSR-11-54

美国AII PSR-11-54

|

|

|

|

美国AII氧分析仪传感器PSR-11-52

美国AII PSR-11-52

|

|

|

|

美国AII氧分析仪传感器PSR-11-39

美国AII PSR-11-39

|

|

美国AII氧气传感器,GPR氧燃料电池,PSR氧电极,XLT氧电池

-

类 别: 分析仪器 > 气体检测仪 气体传感器

-

名 称: 美国AII氧气传感器,GPR氧燃料电池,PSR氧电极,XLT氧电池

-

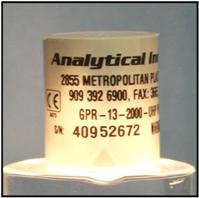

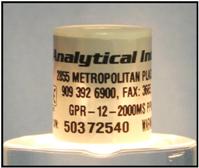

型 号:

GPR-12-2000MS,GPR-12-333,GPR-11-32-4,PSR-12-223

-

品 牌: 美国先进AII/ADV公司

-

参考价格: 书面报价

美国AII(ADV)公司的氧气传感器(氧气传感器、氧电极、氧电池、氧燃料电池)制造技术使得近几十年来的电化学传感器技术实现了革命性的突破, 其将微燃料电池氧传感器的灵敏度提高到了1ppb,寿命长达2-10年,响应时间以及从工艺波动中恢复时间大大缩短,使用温度拓宽到了-30度,稳定性大为提高从而延长了标定周期。另外,AII美国AII(ADV)公司还提供一系列高质量替代传感器,可发和市场上主要厂商的电化学氧传感器互换使用。和市场上主要的氧仪表相比,提供了最好的性能价格比。在绝大多数情况下,AII产品可以替代顺磁氧分析仪,而且实际表现更加优秀。这是因为和顺磁氧传感器相比,电化学传感器稳定性好,受温度、流量、压力的影响小,不受振动、安装角度等因素的影响(这对便携式分析仪而言尤为重要),对样气水份、尘等杂质含量的要求比较低,在传感器使用寿命周期内,灵敏度不因为样气中含有一定量的水份或尘而下降,而且对样气预处理系统要求低。AII/ADV公司所开发的氧传感器 其将微燃料电池氧传感器的灵敏度提高到了1ppb,寿命长达2-10年,响应时间以及从工艺波动中恢复时间大大缩短,使用温度拓宽到了-30度,稳定性大为提高从而延长了标定周期。另外,AII美国AII(ADV)公司还提供一系列高质量替代传感器,可发和市场上主要厂商的电化学氧传感器互换使用。和市场上主要的氧仪表相比,提供了最好的性能价格比。在绝大多数情况下,AII产品可以替代顺磁氧分析仪,而且实际表现更加优秀。这是因为和顺磁氧传感器相比,电化学传感器稳定性好,受温度、流量、压力的影响小,不受振动、安装角度等因素的影响(这对便携式分析仪而言尤为重要),对样气水份、尘等杂质含量的要求比较低,在传感器使用寿命周期内,灵敏度不因为样气中含有一定量的水份或尘而下降,而且对样气预处理系统要求低。AII/ADV公司所开发的氧传感器 (氧气传感器、氧电极、氧电池、氧燃料电池)对氧有极好的选择性,要可以测量低至小于1ppb、高到100%的氧。样气中的氧在敏感电极上发生化学反应,产生和浓度成比例的电流信号。所输出的电流信号在指定的所有测量内均为线性,并且在整个正常使用寿命周期内保持不变。其它竞争者所制造的传感器很难与之相比。 (氧气传感器、氧电极、氧电池、氧燃料电池)对氧有极好的选择性,要可以测量低至小于1ppb、高到100%的氧。样气中的氧在敏感电极上发生化学反应,产生和浓度成比例的电流信号。所输出的电流信号在指定的所有测量内均为线性,并且在整个正常使用寿命周期内保持不变。其它竞争者所制造的传感器很难与之相比。

GPR-13-2000UHP氧气传感器、GPR-12-2000MS氧电极、GPR-12-333氧电池、GPR-11-32-4氧燃料电池、PSR-12-223氧电极、XLT-12-333、GPR-12-100-M、XLT-12-100-M、GPR-11-120-OP、GPR-11-120-RTS、GPR-11-120-4、GPR-11-60-4、GPR-11-75-F、GPR-11-60、XLT-11-24、XLT-11-32-4、XLT-11-32-RT、GPR-11-21-RT、A-2675氧燃料电池、OSV-31-1、OSV-42-1、PSR-12-223、XLT-12-223、PSR-11-15D、9212-0、PSR-11-21、GPR-11-917-J、PSR-11-37-4、PSR-11-75-KE氧电池、SAF-11-02-E、SAF-11-02-I氧电极、XLT-11-15氧气传感器,AII氧分析仪GPR-1200/GPR-1100GPR-1500传感器:GPR-12-333/GPR-12-100-M或酸性电池XL-12-333;AII氧分析仪传感器GPR-2000配GPR-11-21-RT/XLT24-RT;纯氧分析仪变送器GPR-2500MO配1-120-4氧分析仪传感器常量氧变送器GPR-2500配GPR-11-32-4或酸性电池XLT-11-32-4。

AII/ADV公司氧电极工作原理

AII/ADV公司所开发的传感器对氧有极好的选择性,要可以测量低至小于1ppb、高到100%的氧。样气中的氧在敏感电极上发生化学反应,产生和浓度成比例的电流信号。所输出的电流信号在指定的所有测量内均为线性,并且在整个正常使用寿命周期内保持不变。其它竞争者所制造的传感器很难与之相比。

创新性设计、特有的制造技术、电极和电解质材料等重要因素综合在一起优化了这些氧传感器的关键特性,使得近几十年来的电化学传感器技术实现了一次真正的飞跃。

0-100ppb满量程的Pico-lon “HP”

系列传感器

传感器技术主要的突破之一:灵敏度<1ppb、超快速恢复、极好的信噪比和稳定性。GPR和XLT微量氧传感器、常量氧传感器、氢中氧传感器、高纯度氧传感器、氧纯度传感器

0-1ppm满量程Pico-lon “MS” 系列传感器

由“HP”系列的传感器演变而来,强信号输出确保了室内应用无温控条件下工作时的长期稳定性。

0-10pp满量程的先进电化学燃料池传感器

GPR和XLT-12t系列传感器表现出低含量下更好的稳定性、更快的恢复(1小时内由空气恢复至10ppm)等特性,寿命长达18-24个月,GPR和XLT微量氧传感器、常量氧传感器、氢中氧传感器、高纯度氧传感器、氧纯度传感器

提供长达1年的质量保证。次低温(低至-30度)工作温度下可提供0-100ppm的低量程。

0-1%至0-100%满量程的先进电化学燃料电池传感器

GPR和XLT-11系列传感器具有比目前市场上的任何电化学传感器更好的稳定、长得多的寿命(在空气中长达10年)和更宽的工作温度范围(-40度~+50度)。

90-100%满量程“OP”系列氧纯度传感器

电化学传感器技术的主要突破之一:克服了电化学传感器在该应用场合下寿命短、信号输出下降快的致命弱点。该系列传感器表现出了极好的稳定性、无漂移,在100%氧中寿命长达2年。GPR-12-333Oxygen

Sensor,GPR-12-333ppm Oxygen

Sensor,GPR-12-2000MSppb Oxygen

Sensor,GPR-11-12-4High Purity Oxygen Sensor

替代氧传感器

AII还设计出一系列高质量的替代传感器,用于直接替代Teledyne、MSA、Figaro 其它厂商的氧传感器。

传感器选型通用指导GPR-13-2000UHP氧气传感器、GPR-12-2000MS氧电极、GPR-12-333氧电池、GPR-11-32-4氧燃料电池、PSR-12-223氧电极、XLT-12-333、GPR-12-100-M、XLT-12-100-M、GPR-11-120-OP、GPR-11-120-RTS、GPR-11-120-4、GPR-11-32-4、GPR-11-60-4、GPR-11-75-F、GPR-11-60、XLT-11-24、XLT-11-32-4、XLT-11-32-RT、GPR-11-21-RT、A-2675氧燃料电池、 OSV-31-1、OSV-42-1、PSR-12-223、XLT-12-223、PSR-11-15D、9212-0、PSR-11-21、GPR-11-917-J、PSR-11-37-4、PSR-11-75-KE氧电池、SAF-11-02-E、SAF-11-02-I氧电极、XLT-11-15氧气传感器,AII氧分析仪GPR-1200/GPR-1100GPR-1500传感器:GPR-12-333/GPR-12-100-M或酸性电池XL-12-333;AII氧分析仪传感器GPR-2000配GPR-11-21-RT/XLT24-RT;纯氧分析仪变送器GPR-2500MO配1-120-4氧分析仪传感器常量氧变送器GPR-2500配GPR-11-32-4或酸性电池XLT-11-32-4。AII氧气传感器专门设计用于背景气体中含有0.5%-100%CO2和其它酸性气体的连续测量。合气体或间歇式测量CO2和其它酸性气体中的氧。间歇式测量定义为微量氧在15分钟测量后用空气或氮气吹扫15分钟。 OSV-31-1、OSV-42-1、PSR-12-223、XLT-12-223、PSR-11-15D、9212-0、PSR-11-21、GPR-11-917-J、PSR-11-37-4、PSR-11-75-KE氧电池、SAF-11-02-E、SAF-11-02-I氧电极、XLT-11-15氧气传感器,AII氧分析仪GPR-1200/GPR-1100GPR-1500传感器:GPR-12-333/GPR-12-100-M或酸性电池XL-12-333;AII氧分析仪传感器GPR-2000配GPR-11-21-RT/XLT24-RT;纯氧分析仪变送器GPR-2500MO配1-120-4氧分析仪传感器常量氧变送器GPR-2500配GPR-11-32-4或酸性电池XLT-11-32-4。AII氧气传感器专门设计用于背景气体中含有0.5%-100%CO2和其它酸性气体的连续测量。合气体或间歇式测量CO2和其它酸性气体中的氧。间歇式测量定义为微量氧在15分钟测量后用空气或氮气吹扫15分钟。

|

其将微燃料电池氧传感器的灵敏度提高到了1ppb,寿命长达2-10年,响应时间以及从工艺波动中恢复时间大大缩短,使用温度拓宽到了-30度,稳定性大为提高从而延长了标定周期。另外,AII美国AII(ADV)公司还提供一系列高质量替代传感器,可发和市场上主要厂商的电化学氧传感器互换使用。和市场上主要的氧仪表相比,提供了最好的性能价格比。在绝大多数情况下,AII产品可以替代顺磁氧分析仪,而且实际表现更加优秀。这是因为和顺磁氧传感器相比,电化学传感器稳定性好,受温度、流量、压力的影响小,不受振动、安装角度等因素的影响(这对便携式分析仪而言尤为重要),对样气水份、尘等杂质含量的要求比较低,在传感器使用寿命周期内,灵敏度不因为样气中含有一定量的水份或尘而下降,而且对样气预处理系统要求低。AII/ADV公司所开发的氧传感器

其将微燃料电池氧传感器的灵敏度提高到了1ppb,寿命长达2-10年,响应时间以及从工艺波动中恢复时间大大缩短,使用温度拓宽到了-30度,稳定性大为提高从而延长了标定周期。另外,AII美国AII(ADV)公司还提供一系列高质量替代传感器,可发和市场上主要厂商的电化学氧传感器互换使用。和市场上主要的氧仪表相比,提供了最好的性能价格比。在绝大多数情况下,AII产品可以替代顺磁氧分析仪,而且实际表现更加优秀。这是因为和顺磁氧传感器相比,电化学传感器稳定性好,受温度、流量、压力的影响小,不受振动、安装角度等因素的影响(这对便携式分析仪而言尤为重要),对样气水份、尘等杂质含量的要求比较低,在传感器使用寿命周期内,灵敏度不因为样气中含有一定量的水份或尘而下降,而且对样气预处理系统要求低。AII/ADV公司所开发的氧传感器 (氧气传感器、氧电极、氧电池、氧燃料电池)对氧有极好的选择性,要可以测量低至小于1ppb、高到100%的氧。样气中的氧在敏感电极上发生化学反应,产生和浓度成比例的电流信号。所输出的电流信号在指定的所有测量内均为线性,并且在整个正常使用寿命周期内保持不变。其它竞争者所制造的传感器很难与之相比。

(氧气传感器、氧电极、氧电池、氧燃料电池)对氧有极好的选择性,要可以测量低至小于1ppb、高到100%的氧。样气中的氧在敏感电极上发生化学反应,产生和浓度成比例的电流信号。所输出的电流信号在指定的所有测量内均为线性,并且在整个正常使用寿命周期内保持不变。其它竞争者所制造的传感器很难与之相比。

OSV-31-1、OSV-42-1、PSR-12-223、XLT-12-223、PSR-11-15D、9212-0、PSR-11-21、GPR-11-917-J、PSR-11-37-4、PSR-11-75-KE氧电池、SAF-11-02-E、SAF-11-02-I氧电极、XLT-11-15氧气传感器,AII氧分析仪GPR-1200/GPR-1100GPR-1500传感器:GPR-12-333/GPR-12-100-M或酸性电池XL-12-333;AII氧分析仪传感器GPR-2000配GPR-11-21-RT/XLT24-RT;纯氧分析仪变送器GPR-2500MO配1-120-4氧分析仪传感器常量氧变送器GPR-2500配GPR-11-32-4或酸性电池XLT-11-32-4。AII氧气传感器专门设计用于背景气体中含有0.5%-100%CO2和其它酸性气体的连续测量。合气体或间歇式测量CO2和其它酸性气体中的氧。间歇式测量定义为微量氧在15分钟测量后用空气或氮气吹扫15分钟。

OSV-31-1、OSV-42-1、PSR-12-223、XLT-12-223、PSR-11-15D、9212-0、PSR-11-21、GPR-11-917-J、PSR-11-37-4、PSR-11-75-KE氧电池、SAF-11-02-E、SAF-11-02-I氧电极、XLT-11-15氧气传感器,AII氧分析仪GPR-1200/GPR-1100GPR-1500传感器:GPR-12-333/GPR-12-100-M或酸性电池XL-12-333;AII氧分析仪传感器GPR-2000配GPR-11-21-RT/XLT24-RT;纯氧分析仪变送器GPR-2500MO配1-120-4氧分析仪传感器常量氧变送器GPR-2500配GPR-11-32-4或酸性电池XLT-11-32-4。AII氧气传感器专门设计用于背景气体中含有0.5%-100%CO2和其它酸性气体的连续测量。合气体或间歇式测量CO2和其它酸性气体中的氧。间歇式测量定义为微量氧在15分钟测量后用空气或氮气吹扫15分钟。