■Description

GP2Y0D810Z0F is distance measuring

sensor unit,

composed of an integrated

combination of PSD (position

sensitive detector) , IRED (infrared

emitting diode) and signal

processing circuit.

The variety of the reflectivity of

the object, the environmental

temperature and the operating

duration are not influenced easily

to the distance detection because of

adopting the triangulation method.

The output voltage of this sensor

stays high in case an object exists

in the specified distance range. So

this sensor can also be used as

proximity sensor.

■Agency approvals/Compliance

1. Compliant with RoHS directive

(2002/95/EC)

■Applications

1. Touch-less switch

(Sanitary equipment, Control of

illumination, etc.)

2. Robot cleaner

■Features

1. Digital output type

2. Short distance type

Detecting distance : Typ. 100 mm

3. Low profile

Package size : 13.6×7×7.95 mm

4. Consumption current : Typ. 5 mA

5. Battery drive compatible

Supply voltage : 2.7 to 6.2 V

6. Sunlight tolerance

7. Add Vin terminal, and an external

transistor of Vcc line is

unnecessary at intermittent

operating.

■Block diagram

■Outline Dimensions

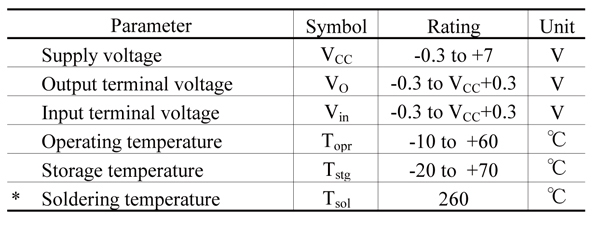

■Absolute Maximum Ratings

■Electro-optical Characteristics

(*1) ICC1 : (LED Emitting time :

Typ. 20 μs × 8 times), ICC2 :

(Emitting time : Typ. 20 μs × 15

times), LED Pulse Current : Typ. 70

mA

(*2) Using reflective object : White

paper (Made by Kodak Co., Ltd. gray

cards R-27?white face, reflectance ;

90%) (*3) Output voltage switch has

a hysteresis width. The distance

specified by L should be

the distance which the output turns

from L to H in case an object moves

to the sensor.

■Recommended operating conditions

Fig. 1 Timing chart

Fig. 2 Example of distance measuring

characteristics (output)

■Notes

●Advice for the optics

The lens of this device needs to

be kept clean. There are cases that

dust, water or oil and so on

deteriorate

the characteristics of this device.

Please consider in actual

application.

Please don’t do washing. Washing

may deteriorate the characteristics

of optical system and so on.

Please confirm resistance to

chemicals under the actual usage

since this product has not been

designed against washing.

●Advice for the characteristics

In case that an optical filter is

set in front of the emitter and

detector portion, the optical filter

which has the most

efficient transmittance at the

emitting wavelength range of LED for

this product (λ = 870 ± 70nm), shall

be recommended to use. Both faces of

the filter should be mirror

polishing. Also, as there are cases

that the characteristics may not be

satisfied according to the distance

between the protection cover and

this product or the thickness of the

protection cover, please use this

product after confirming the

operation sufficiently in actual

application.

In case that there is an object

near to emitter side of the sensor

between sensor and a detecting

object, please use this device after

confirming sufficiently that the

characteristics of this sensor do

not change by the object.

When the detector is exposed to

the direct light from the sun,

tungsten lamp and so on, there are

cases that it can not measure the

distance exactly. Please consider

the design that the detector is not

exposed to the direct light from

such light source.

? Distance to a mirror reflector can

not be sometimes measured exactly.

In case of changing the mounting

angle of this product, it may

measure the distance exactly.

In case that reflective object has

boundary line which material or

color etc. are excessively

different, in order to decrease

deviation of measuring distance, it

shall be recommended to set the

sensor that the direction of

boundary line and the line between

emitter center and detector center

are in parallel.

In order to decrease deviation of

measuring distance by moving

direction of the reflective object,

it shall be recommended to set the

sensor that the moving direction of

the object and the line between

emitter center and detector center

are vertical.

●Notes on handling

There are some possibilities that

the internal components in the

sensor may be exposed to the

excessive mechanical

stress. Please be careful not to

cause any excessive pressure on the

sensor package and also on the PCB

while assembling this product.

? Soldering shall be done with a

soldering iron and below 260℃, less

than 5s and maximum 2 times.

Also, please pay attention not to

put outer force on lead terminals

while soldering. Please do not apply

flow soldering because it may damage

optical lens of the device.

●Presence of ODC etc.

This product shall not contain the

following materials.

And they are not used in the

production process for this product.

Regulation substances : CFCs, Halon,

Carbon tetrachloride,

1.1.1-Trichloroethane

(Methylchloroform) Specific

brominated flame retardants such as

the PBB and PBDE are not used in

this product at all.

This product shall not contain the

following materials banned in the

RoHS Directive (2002/95/EC).

Lead, Mercury, Cadmium, Hexavalent

chromium, Polybrominated biphenyls

(PBB), Polybrominated diphenyl

ethers (PBDE).

■Package specification

■Important Notices

The circuit application examples in

this publication are provided to

explain representative

applications of SHARP devices and

are not intended to guarantee any

circuit design or license any

intellectual property rights. S H

A R P takes no responsibility for

any problems related to any

intellectual property right of a

third party resulting from the use

of SHARP's devices.

Contact SHARP in order to obtain

the latest device specifi- cation

sheets before using any SHARP

device. S H A R P reserves the

right to make changes in the

specifications, characteristics,

data, materials, structure, and

other contents described herein at

any t i m e w i t hout notice in

order to improve design or

reliability. Manufacturing locations

are also subject to change without

notice.

Observe the following points

when using any devices in this

publication. SHARP takes no

responsibility for damage caused by

improper use of the devices which

does not meet the conditions and

absolute maximum ratings to be used

specified in the relevant

specification sheet nor meet the

following condi- tions:

(i) The devices in this publication

are designed for use in general

electronic equipment designs such

as:

--- Personal computers

--- Office automation equipment

--- Telecommunication equipment

[terminal]

--- Test and measurement equipment

--- Industrial control

--- Audio visual equipment

--- Consumer electronics

(ii) Measures such as fail-safe

function and redundant design should

be taken to ensure reliability and

safety when SHARP devices are used

for or in connection

with equipment that requires higher

reliability such as:

--- Transportation control and

safety equipment (i.e., aircraft,

trains, automobiles, etc.)

--- Traffic signals

--- Gas leakage sensor breakers

--- Alarm equipment

--- Various safety devices, etc.

(iii) SHARP devices shall not be

used for or in connection with

equipment that requires an extremely

high level of reliability and safety

such as:

--- Space applications

--- Telecommunication equipment

[trunk lines]

--- Nuclear power control equipment

--- Medical and other life support

equipment (e.g., scuba).

If the SHARP devices listed in

this publication fall within the

scope of strategic products

described in the Foreign Exchange

and Foreign Trade Law of Japan, it

is necessary to obtain approval to

export such SHARP devices.

This publication is the

proprietary product of SHARP and is

copyrighted, with all rights

reserved. Under the c o p y - right

laws, no part of this publication

may be r e p r o - duced or

transmitted in any form or by any

means, electronic or mechanical, for

any purpose, in whole or in part,

without the express written

permission of S

HARP. Express written permission is

also required before any use of this

publication may be made by a third

party.

Contact and consult with a SHARP

representative if t h e r e are any

questions about the contents of this

publication.